The Axemakers of Cornwallis Township

- marcsitkin

- Dec 3, 2020

- 7 min read

Updated: May 15, 2023

Fig. 1. The Blenkhorn factory, Canning, N.S.

Excerpted from The Chronicle Vol. 34 no.1, March 1981

by Robin H. Wyllie

This article covers but a fraction of the documentary information discovered during the project. Much of it, for example the Blenkhorn account books from 1922 until 1963, has not yet been fully assessed or evaluated.

The project was commenced in 1978. Advice was sought from Bob Frame of the Nova Scotia Museum who gave a copy of the 1977 Chronicle article by Stephen White, a few names to contact and a gentle push in the right direction. (See White, Checklist of Woodworking Tool Mfrs. in New Brunswick and Nova Scotia, Chronicle, Sept. 77).

These initial contacts exhausted, I was left with a general and, in the main, unsubstantiated picture of the edged tool manufactory in the province. I decided to concentrate on one area at a time. As most of the information accumulated to this point was from the Cornwallis Township area it was decided to start there.

A form letter was composed and sent with a questionnaire to every family in the area whose surnames had appeared in the initial stages of the project. The results were almost overwhelming. Personal accounts, references, tools, photo graphs and documents were received in sufficient quantity to fill nearly all of the information gaps, especially with respect to the Blenkhorn operation.

This “Interim Report” is a tribute to all these relatives and descendants of the Cornwallis Axemakers who have given of their time and made it possible.

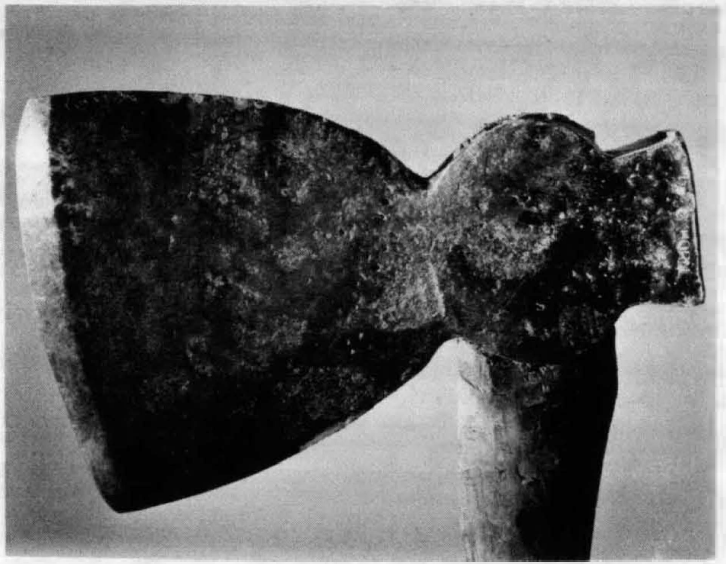

Fig. 2. A Benjamin Eaton axe. Broad side axe, Kent style. Nova Scotia Museum.

Historical Background Cornwallis Township is one of the townships comprising Kings County. It lies on the upper Bay of Fundy on the shores of the Minas Basin. Sheltered by the North and South mountain ranges of the Annapolis Valley, its fertile meadows, saltmarsh and mud flat were first settled by peasants from Western France. These Acadians were shipped in the mid-seventeenth century by the French government with a view to establishing a constant supply of provisions and manpower for the French forts.

Their inability to come to terms with the Governors of Halifax and Massachusetts forced their deportation in 1755. Five years later, twenty-two ship-loads of “Planters” arrived from New England to take over the vacated farm and dyke-land and guard the back door to Halifax.

Economic Background The New England settlers were farmers and craftsmen who brought with them all of the goods and chattels necessary to re-establish their comfort-able colonial lifestyle in the new lands.

David Eaton of Tolland, Connecticut, was a typical example. Attracted by the six hundred and sixty-six acre land grant he settled down to prosper and found a dynasty. He, his fellow planters, and the well-to-do Yorkshire farmers across the basin were responsible for the foundation of much of Nova Scotia's 19th century industry.

The growth of these industries, in particular those of shipbuilding, lumbering, farming and mining, was stimulated by the American Revolution and the cessation of trade with New England. Forced into an isolated economic pocket, the Nova Scotians began to “make do” for themselves. The sheltered Minas Basin became a major shipbuilding area and, because of demand and availability of raw materials in the surrounding counties, shipwrights and blacksmiths flourished. It was but a matter of time before someone began to specialize in the manufacture of edged tools.

Fig. 3. A George W. Eaton axe. Broad felling axe, Kent style. Wyllie collection.

Benjamin Eaton Blacksmith and direct descendant of “planter” David Eaton, he was born in 1822 at Lower Canard, south of Canning. He bought the Sheffield Mills Complex in 1865, adding a wood planing mill and his axe factory. The thirty acre pond, the largest in the province, served these in addition to the original grist and saw mills.

Competition from the grist mill at Steam Mill village and Blenkhorn's steam factory in Canning seem to have had little or no effect upon his edged tool business into which he had taken his two sons as they became old enough. Both became skilled tool makers and continued working with their father until 1884.

At this time, aged 62, Benjamin drained the pond and sold the land, most of it to his two sons, for the then enormous sum of three thousand one hundred and seventy-five dollars. The axe making machinery was sold to James Blenkhorn and Benjamin's son William Edwin was given the job of temperer in the new factory. The other son James Everett Eaton turned his interest to farming.

A number of Benjamin's broad axes are still to be found in the area. Those examined were all Kent style and stamped B. Eaton Cornwallis.

He died April 22, 1906, aged 84.

Fig. 4. A Blenkhorn broad side axe, Scotch style. Wyllie collection.

George Wiswell Eaton Born 1834 and younger brother of Benjamin was also a skilled axe maker. It is believed that he took over Benjamin's smithy at Sheffield Mills forks when the axe factory was built.

By 1872 he had moved to Berwick. The “Church” map shows his shop located on Main Street adjacent to Ells' Carriage Factory from which he no doubt obtained considerable business.

His axes made during this period show a similarity of design to those of his brother and, although they appear mostly hand forged, could have been made from blanks obtained from Sheffield Mills. The few known examples are Kent type side or felling patterns stamped “G. W. EATON BERWICK” using two separate dies. George Wiswell Eaton is listed as an axe maker in 1890. Correspondence with his granddaughter has indicated that with the closure of the carriage factory he became a dealer in hard and soft coals.

He died June 25, 1919, aged 85.

Thomas Cox First cousin to Benjamin and George Wiswell Eaton, Thomas was reputedly the best maker of single bit “poll” axes as they were called locally. He was located in Kentville and made agricultural and wheelwrights tools in addition to axes but few have been identified.

An axe head in the author's collection, reputedly made by Cox, is entirely hand forged and bears no distinguishing marks. I have been told that he used to brand his wooden handles with a “Tomcat” design but none have come to light. Further research is indicated.

James Blenkhorn Born 1818. Descendant of the Y orkshiremen on the Cumberland shore and a skilled shipwright. As such he worked for a number of years in collaboration with Ebenezer Bigelow the shipbuilder. The families were related by marriage and Blenkhorn moved with the Bigelows from Parrsboro to Kingsport in Cornwallis Township in 1846.

According to family tradition he left Bigelow's employment and went into business for himself in 1850. He maintained his connections with the yard and in 1856 when Bigelow moved to Canning, Blenkhorn followed.

In 1857 Blenkhorn and Bigelow, in partnership with Garland Cox and Christopher Jemson, were owners of the new Canning Steam Factory manufacturing agricultural tools and milling wood. This factory had cost them in the region of 2000 pounds and carried no insurance: nor did Blenkhorn's shop or Bigelow's shipyard.

Early on Sunday morning the 15th of July 1866 the town of Canning burned. Twenty-six stores, dwelling houses, the steam factory, the shipyard and Blenkhorn's shop went up in flames along the Habitant river. Two years later the rebuilt town burned again.

Bigelow, borrowing heavily, survived the decline in shipbuilding until 1855 when the yard failed. To avoid creditors a letter was published to the effect that he and his family had left the country.

James Blenkhorn in the meantime had been thriving in his new shop by the riverside. His two sons Sydney and Hennigar were taken into the business and, seeing what was happening to the shipbuilding industry, Benjamin Eaton's axe making machinery was purchased in 1884. They also acquired the services of Benjamin's son William Edwin who worked for them as temperer, driving to and from his farm at Sheffield Mills each day by carriage.

In 1890 the factory burnt down, at which point son Sydney took over. A new factory was built on cribwork on the old shipyard property and a wharf constructed for unloading coal. New machinery was purchased from the U.S. and a schooner, the “Murray B,” subsequently acquired to supply the new hard and soft coal business.

The Blenkhorns survived another fire in 1912 at which time Sydney's son Scott took over. Scott was a graduate of Mount Allison University and an engineering graduate of Queens. He had a job waiting for him in Ontario when forced to return to Canning. In 1921 he switched the factory over from steam to electricity and managed to get things through the thirties. He was owner-manager, salesman and whatever else was needed, even, in the latter stages, temperer.

Things went quite well during the war period but, finally, after re-equipping the factory in 1955 with modern heat treating equipment, Scott Blenkhorn lost out to the power saw in 1962. The coal business was closed out the following year.

Only a brush-covered mound beside the Habitant river remains as a monument to 120 years of industry.

There are many Blenkhorn axes about, especially the double bits for which they were famous from New Brunswick to Newfoundland. Descriptions may be found in the following list of Tools and Artifacts examined.

Bibliography Church Map, Kings County E-14-13 Sheet 2, 1872 Canning. The Great Fire. Nova Scotia Archives, Vert MS file. Canning Steam Factory. Nova Scotia Archives, Petition to the legislature 1857, RG 5. The Eatons of Kings County. C.E. Eaton, private printing 1979. The Blenkhorn Family Tree. C.W. Blenkhorn, personal research, 1972. The History of Markland or Nova Scotia. R.R. McLeod, private printing, 1903. Grist From The Mills. Sheffield Mills W.R.I. Centennial project 1967. Bits of history of Canning. Ira Cox, clipping from unidentified newspaper.

Acknowledgements I wish to acknowledge and thank the following for their assistance and encouragement: Mr. Robert W. Frame Nova Scotia Museum Mrs. Barbara Eaton Lower Canard, Kings Co. Mr. Ernest L. Eaton Upper Canard, Kings Co. Mr. Fred Joudrie Canning, Kings Co. Mr. Ron Merrick Media Services, Nova Scotia Education Department. Plus the many others who have assisted my research.

Comments